Vinyl wrap damage on commercial vehicles is common but can be mitigated with early detection and prompt repair by skilled technicians using specialized tools. Regular repair and replacement extend vehicle lifespan, enhance market appeal, reduce corrosion, and minimize downtime for fleet managers. Despite high initial costs, long-term benefits include cost savings, higher resale values, and flexible service options.

In today’s commercial fleet landscape, vinyl wrap damage is a common challenge. This article guides you through the intricacies of vinyl wrap repair and replacement on fleet and commercial vehicles. From understanding various types of damage to exploring the step-by-step process, we delve into what fleet managers need to know. Discover the benefits and cost considerations associated with this durable and cost-effective solution for vehicle aesthetics.

- Understanding Vinyl Wrap Damage on Commercial Vehicles

- The Process of Repair and Replacement

- Benefits and Cost Considerations for Fleet Managers

Understanding Vinyl Wrap Damage on Commercial Vehicles

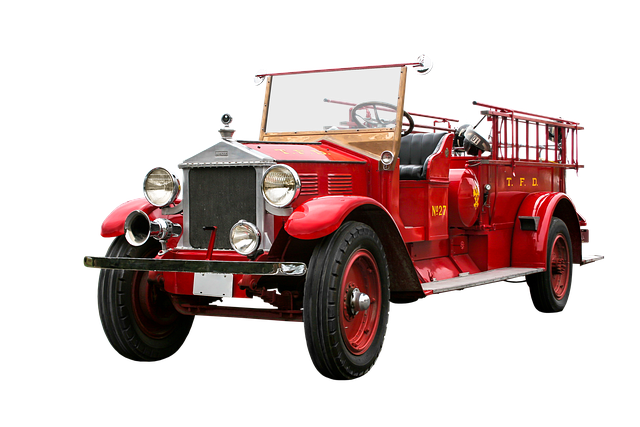

Vinyl wrap damage on commercial vehicles can manifest in various forms, from small tears and cracks to more extensive delaminations and color fading. These issues often arise due to exposure to harsh weather conditions, road debris, and everyday wear and tear. In the case of fleet vehicles, regular use and frequent washing can accelerate degradation, making prompt attention crucial. Early detection of vinyl wrap damage is essential for effective repair and maintenance, ensuring these vehicles maintain their professional appearance and protective properties.

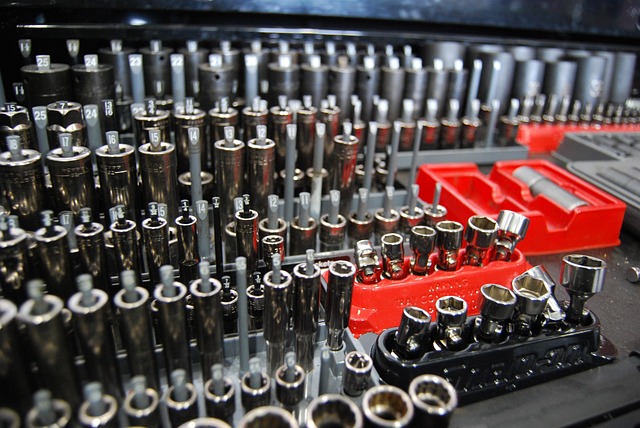

Vinyl wrap repair replacement involves skilled technicians using specialized tools and materials to restore or replace damaged sections. This process not only addresses aesthetic concerns but also reinforces the vehicle’s structural integrity, protecting its underbody from potential corrosion and other forms of damage. A well-executed vinyl wrap repair can extend the lifespan of commercial vehicles, making them stand out in a competitive market while reducing the need for frequent car body repairs.

The Process of Repair and Replacement

The process of repairing and replacing a vinyl wrap on a fleet or commercial vehicle involves several meticulous steps. It begins with assessing the extent of damage, which can range from minor scratches and dents to significant tears or bulges in the wrap. For smaller issues, such as light scrapes, a simple repair kit can be used to fill and smooth out the damaged area, ensuring an even finish once the wrap is re-applied. This method not only saves time but also money, making it ideal for regular maintenance.

For more extensive damage, particularly on larger vehicles like trucks or buses, a complete vinyl wrap replacement might be necessary. This involves carefully removing the existing wrap, inspecting the underlying car body restoration for any structural issues, and then applying a new layer of vinyl. Throughout this process, tire services may also be required to ensure the vehicle is in optimal condition. Skilled technicians use specialized tools and techniques to achieve a seamless fit, maintaining the vehicle’s aesthetics while enhancing its overall appearance and protection.

Benefits and Cost Considerations for Fleet Managers

For fleet managers, regular vinyl wrap repair replacement offers a multitude of advantages. Firstly, it enhances vehicle aesthetics, ensuring that each car maintains a professional and consistent look, which is vital for corporate branding and customer impressions. Secondly, prompt repairs prevent minor issues from escalating into costly damage, thereby reducing overall maintenance expenses. Efficient vehicle body repair services can even provide same-day solutions, minimizing downtime for commercial fleets.

Cost-wise, while upfront investment in vinyl wrap repair replacement might seem significant, it pays off in the long term. Preventative measures reduce the need for extensive vehicle paint repair, and a well-maintained fleet enjoys higher resale values. Moreover, many companies offer flexible packages and leasing options, making these services accessible without straining budgets.

Vinyl wrap repair and replacement is a valuable service for fleet managers, offering both aesthetic and functional benefits. By understanding common damage types and implementing efficient repair processes, businesses can maintain their commercial vehicles’ appealing appearances and ensure optimal performance. This cost-effective solution allows fleets to extend vehicle lifespans, reduce downtime, and make a positive impression on clients without breaking the bank. Embracing vinyl wrap repairs is a strategic move towards enhancing fleet management and keeping operations running smoothly.